1 machine for more than 100 different bag types

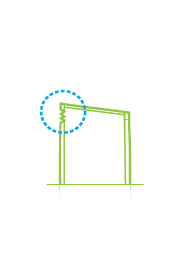

Thanks to the unique versatility of the VERSATILE-440 (HSV440) series, one vertical packaging machine can create more than 100 bag types! It allows you to accommodate any new requirements dictated by a rapidly evolving market.